Thermal Insulation

For more than eight decades, design professionals have used lightweight concrete masonry and lightweight structural concrete on building facades to reduce energy losses through exterior walls. It is well demonstrated that the thermal resistance of lightweight concrete is considerably less than that of ordinary concrete, and this relationship extends to aggregates in the loose state.

Structural lightweight aggregate has been effectively used to surround high-temperature pipelines to lower heat loss. Long-term, high-temperature stability characteristics can be maintained by aggregates that have already been exposed to temperatures of 1100° C (2012° F) during the production process. Other application have included placing lightweight aggregate beneath heated oil processing plants to reduce heat flow to the supporting soils.

Thermal Conductivity

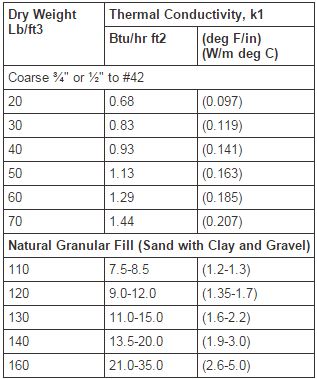

The information on the table below is provided to assist engineers when designing thermally sensitive projects, i.e. frost protection for underground water lines, insulation around or under thermal sensitive vessels, etc.

Moisture has a significant effect on thermal conductivity of granular insulating fills. The thermal conductivity increases about 4% per one-percent moisture for expanded shale, clay and slate lightweight aggregate and increases 7-9% per one-percent moisture for natural sand and gravel.

The practical in-place "k" values for insulating fills depends on the equilibrium moisture content of the fill, which varies depending on the environmental conditions. Where protected conditions exist like core insulation inside concrete masonry units or fills protected by water proof membranes, a "k" value multiplying factor of 1.1 to 1.2 is commonly used. Where unprotected conditions exist like in large geotechnical fills or insulation around underground utility line, a multiplying factor of 1.8 to 1.9 is commonly used.

Weight and Thermal Conductivity Values for Expanded Shale, Clay, & Slate Lightweight Aggregates

k values were taken from "The Thermo-Physical Properties of Masonry and its Constituents, Part 1, Thermal Conductivity of Masonry Materials", by Rudolph C. Valore, Jr.

The k values for fine, or coarse/fine blend, averages 6% lower